Rapid Prototyping. Engineering Precision.

Lower Costs. Improved Performance.

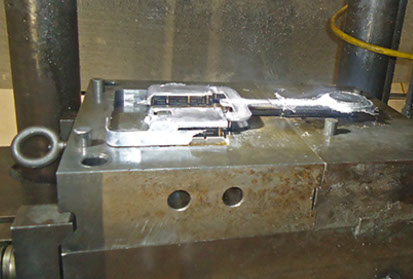

Specialized CNC Machining

Near Net-Shape. Reduced Production Cost.

Thinner Walls. Stronger Parts.

Complex Shapes. High Tolerance Parts.

<

>

Precision Die Casting Services | Since 1968

J&M Precision Die Casting, Inc. has grown since 1968 to a 40,000 square foot facility in Northeast Ohio. In 2015, Rhenium Alloys, Inc. acquired the die casting company specializing in aluminum die casting.

Its employees – the most skilled in the industry – are the hallmark of the operation. We are proud of their talent, employment longevity and unparalleled commitment to high standards. Some unique distinctions that set J&M Precision Die Casting apart are rapid prototyping, high-level engineering precision, and unmatched dedication to service and maintenance. We specialize in high pressure die casting with aluminum, and also develop very high tolerance part designs and tooling for the injection industry.

Doing More For Less

Our versatility enables us to quote competitively and cast competently, whether for long or short runs, large or small parts, simple or complex designs.

We have a wide array of die casting machines and handle many of our secondary operations in house, using our extensive machining centers. We routinely build custom machines for specific customer requirements, in order to reduce their overall costs. Our goal is to efficiently improve the functionality and manufacturability of your designs. We review a design in detail, sharing insights and ideas that allow for a lower-cost end product while improving performance.

WHAT'S New?

ISO 9001:2015

J&M Precision Die Casting

is ISO 9001:2015 certified.

This opens up new markets and opportunities for J&M and ensures that only the highest quality products leave our facility.

ISO 9001 is the international standard that specifies requirements for a quality management system (QMS). Organizations use the standard to demonstrate the ability to consistently provide products and services that meet customer and regulatory requirements.

SpectroMaxx

J&M Precision Die Casting adds SpectroMaxx

We now have the capability to verify metal composition with the addition of our Spectrometer. We can verify Aluminum and Brass alloys. One more step to ensure our customers are receiving the highest quality product.

OUR SPECIALTIES

Aluminum Die Casting

Aluminum, a light weight alloy that possesses high dimensional stability for complex shapes and thin walls, can be cast to near net shape. Near net shape die casting means the initial production of the part is close to the final net shape. This can greatly reduce the need for finishing techniques and eliminate more than 50 percent of production costs.

Cost Reduction & Design Assistance

Our mission is to help our clients improve the functionality and manufacturing of their designs. We review designs in detail and provide insight and ideas, resulting in a lower cost product with improved performance. We can reduce or eliminate secondary operations. Our expert design assistance delivers more for less!

J&M Precision Commitment

- Low cost pricing through advanced creative designing

- Reducing or eliminating unnecessary machining

- Secondary operations to exacting specifications

- Quality control

- Inventory control

- Standing behind our workmanship

J&M Precision Fence Strainers

Increase the tension of your electric fence lines with J&M Precision Die Casting’s high quality, durable in-line fence strainers. Our rugged wire strainers are made with a hot dipped, heavy duty, galvanized strap, heavy duty cast Aluminum for the cog / spool and flapper, and Stainless Steel for the compression spring. Made in the USA, they are durable to stand the test of time. Learn More >>